- Chapters

- descriptions off, selected

- captions settings, opens captions settings dialog

- captions off, selected

- default, selected

This is a modal window.

Beginning of dialog window. Escape will cancel and close the window.

End of dialog window.

Hardwiring the future

Before the new cell and gene production unit in Stein was set to start operations in late 2019, the newly formed team was going through a hard training regime. But motivation to be part of a cutting-edge technology platform ensured that the work spirit remained high during this challenging phase.

By Goran Mijuk

- Chapters

- descriptions off, selected

- captions settings, opens captions settings dialog

- captions off, selected

- default, selected

This is a modal window.

Beginning of dialog window. Escape will cancel and close the window.

End of dialog window.

Table of contents

Table of contents Every move counts

Every move counts Up to the challenge

Up to the challengePublished on 01/06/2020

It was another hard day for the fledgling cell and gene team in Stein, but not because of the bad weather, which had taken an unexpected turn for the worse in mid-March in 2019. For eight hours, associates were training intensively, as they had been in the weeks and months before – hardwiring the myriad steps that their new job would soon require them to do faultlessly every day.

Exercising either in pairs, with one colleague verifying every move made by his or her peer, or under the supervision of a coach, all of the team members of the cell and gene unit were fully focused on the tasks at hand, each of them acutely aware of the high stakes.

A few months later, all of them knew, their dry run would come to an end and the first patient batch would arrive from a hospital at this new cell and gene facility, which is located roughly 30 kilometers from Basel. They would be responsible for genetically modifying patients’ T-cells and ready them to hunt for cancer. No room for mistakes. No room for second thoughts.

Bjoern Giner knew all about the tension which inevitably rises when the first batch is about to arrive. He has worked in Morris Plains for the past few years, where Novartis had built the first industrial cell and gene facility, and still vividly remembered being part of the team that executed a chimeric antigen receptor T-cell therapy, better known under its abbreviation CAR-T, for the first time.

“I had worked in drug discovery before, where you’re a long way from the patient. But with the move to the cell and gene unit in the United States, that changed completely,” Bjoern Giner explained, when I met him for a short chat with several of his colleagues after a day’s challenging work in Stein. “When we handled the first batch I felt nervous and excited at the same time. Never before in my career as a medical scientist did I feel so close to a single patient. Every step we took had a direct impact on a patient’s life. It was a completely different kind of work.”

Since his first batch, Bjoern has worked on hundreds of CAR-T therapies. Given his long experience in the field, he acted as a coach in Stein tasked to educate his new colleagues about the technical aspects of the complex production process, taking great pains to explain each incremental stage of the long procedure, which – in its entirety – fills a 1000-page manual.

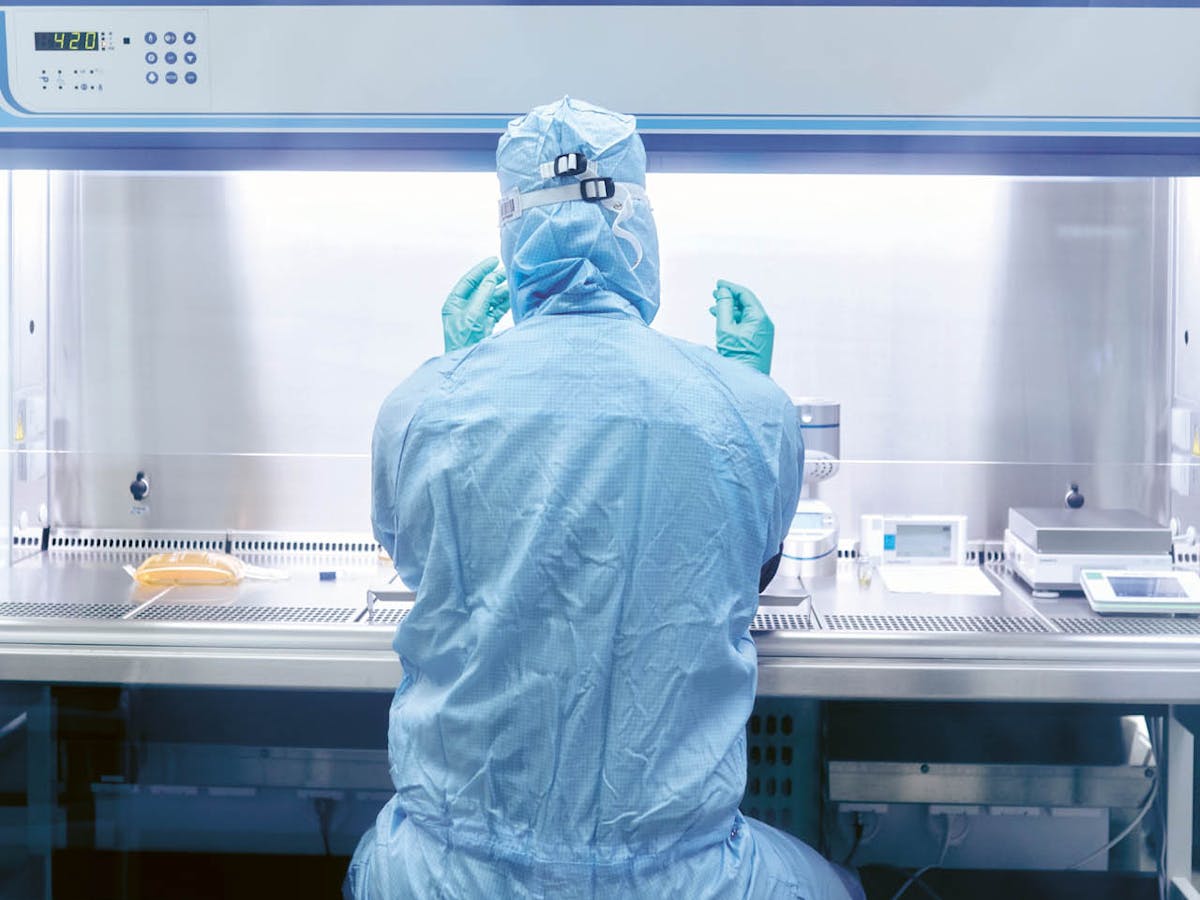

An associate is standing in front of a biosafety cabinet. Behind her, so-called manufacturing execution systems allow associates to document their work without the need for paper.

Bjoern Giner did not tire of repeating how the blood sample is thawed and washed after its arrival from the hospital, how the T-cells are extracted with the help of magnetic beads and then genetically modified with a viral vector that carries a new gene capable of detecting and killing cancer cells. Time and again, he explained how the viral vector is transduced into the T-cells and how the vector is later washed out before the modified T-cells are put in a bioreactor to grow in sufficient numbers to help patients fight their cancers.

Giner knew that every movement of the hand counts. But – more importantly – he aimed to imbue his colleagues, many of whom had never worked with this technology before, with a sense of confidence that they are up to the task.

“Bjoern is a great coach not only because he is a cell and gene process expert,” said Drazen Jovic. “What makes him a great teacher is the way he helps us come to terms with the process, his calm and considerate personality, which gives us room to develop and become experts ourselves.”

Drazen Jovic, like his two other colleagues, Melanie Axmann and Sven Panakkaparambil, was a newcomer to the field of gene technology, having previously worked in Schweizerhalle as a chemicals operator. “I heard it in the news in 2018 when it was announced that Novartis would build a new cell and gene facility in Stein. I didn’t know a lot about the technology and started to research the topic before deciding to take the chance,” he said.

“What makes him a great teacher is the way he helps us come to terms with the process, his calm and considerate personality, which gives us room to develop and become experts ourselves.”

Drazen Jovic

He was trained as a cell processing specialist, after having passed an aptitude test, in which coaches assess a candidate’s dexterity in working with pipettes and other gene technology hardware, as well as their English language skills and their ability to work calmly and remain focused under the special conditions prevailing in a cell and gene facility.

The workflow is fundamentally different from traditional chemicals or solid tablets production. The work and production areas are compartmentalized according to safety and aseptic standards.

Workers wear different protective apparel in each zone, which can take several minutes to put on, requiring them to stay in the designated work area for hours on end, as short breaks are impractical. “It’s far from easy,” says Wolfgang Schick, a technical trainer at the unit, who guided us through the facility. “Except in an emergency, getting out of the safety zones requires time, so they can’t change location easily as in other work situations.”

Every movement of the hand counts. Associates are exercising these movements time and again to gain security in handling the patient batches.

Despite the demanding and complex work conditions, team members were all up to the challenge.

“This is an exciting time,” said Sven Panakkaparambil, who works in the cell and gene site’s Quality Assurance team. “We are a sort of technological frontrunner and all of us are extremely motivated to do our work. To be part of the team, everyone knows, is a huge opportunity and makes many of us extremely proud to be in this pioneering project.”

Of course, all members of the cell and gene team were fully aware of the difficulties and risks that CAR-T therapy entails. But no one was giving in. “I’m not scared,” said Drazen Jovic. “I have a lot of respect for what awaits us and I feel that we are being trained in the best possible way and that, once the first blood batch arrives, we are up to the task and can help each patient fight cancer.”

Bjoern Giner nodded in approval. He knew that unexpected challenges may arise. But he also knew that, in any such situation, everyone will go the extra mile. “This is about saving patients’ lives. Nothing could be more motivating or fulfilling. I am sure that everyone feels the same.”

By late 2019, the team was able to work on the first patient batch. The months-long hardwiring had paid off.

“We are a sort of technological frontrunner and all of us are extremely motivated to do our work. To be part of the team, everyone knows, is a huge opportunity and makes many of us extremely proud to be in this pioneering project.”

Sven Panakkaparambil