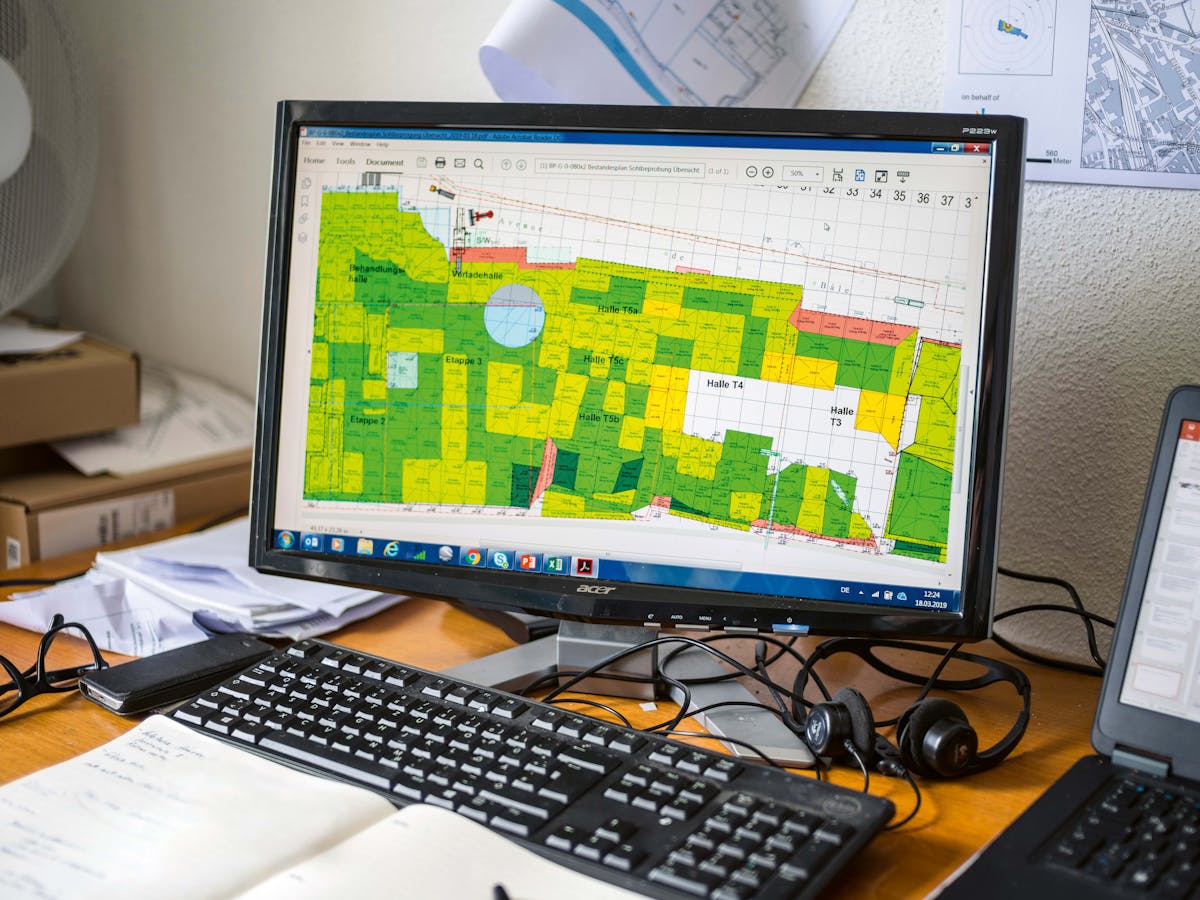

Overview of the current status of the project in the logistics center.

Published on 01/07/2021

The timing could not have been worse. Just a few days before the Ascension holiday in 2019, the bunker conveyor belt transporting contaminated gravel from the tents on the STEIH remediation site to the transport vessel broke down.

“We had repeatedly changed the conveyor belt to avoid a possible breakdown,” said Peter Michel, who was running day-to-day operations on the remediation site. “But when it died on us just two days before the Ascension holiday, most likely due to a piece of iron, we found ourselves in a very difficult situation.”

The conveyor belt broke down late Monday afternoon. By 1800 CET on Wednesday, work was scheduled to stop ahead of the public holiday. Without a solution, the transport vessel on the Rhine would be stuck for a few days, leading to higher costs as well as jeopardizing the overall remediation plans. Calling in external mechanics would have taken too long, Michel recalls.

“It was unlikely that the mechanics would appear the next day and fix the problem on the same day so we could resume loading. So I joined my colleagues in the tent, where we formed two separate teams that worked in tandem until we solved the problem.”

Throughout the project, Michel, whose main job was to coordinate day-to-day operations and look after logistics, took the opportunity to lead by example and do all the vital tasks himself if need be. He expected the same of his team members, who numbered around 17 to 20 people at peak times.

“We were a small team and had to adjust quickly, almost every day, to keep the site going,” Michel said. “When the conveyor belt broke down, I decided to work in the tent, too, to motivate my colleagues to get the job done in time and prove to them that I was not just asking a lot of them but was prepared to do the same myself.”

Working in the tents was no piece of cake. Not only did workers need to don heavy and unwieldy protective gear. Temperatures were also tropical, to say the least. “In summer, it was not unusual for temperatures in the tent to reach 40 degrees Celsius or more. Working more than one hour in these conditions was not feasible. After 30 minutes, workers would need to get out to take a rest.”

After the conveyor belt broke down, two teams worked in tandem: While Michel worked with his team in the tent, the other team members took a rest from the hard working conditions. This went on for about 20 hours until the bunker conveyor belt was operational again and the ship loaded up so that it could start its journey to the Netherlands before the Ascension holiday.

“Without the flexibility that everyone showed, we would not have succeeded in completing the remediation project,” Michel said. “Neither in emergencies nor during normal operations.”

Michel explained that rapid adjustments were paramount even in day-to-day operations and that associates had to perform different kinds of work depending on the tasks involved. “In general, a geologist would take soil samples and inform us about the level of toxicity. I would then advise how the material would be treated and transported – whether it would be shipped in barrels if highly contaminated, in containers or by ship if the material was only lightly contaminated.”

Workers would then be selected for the daily tasks, which could vary substantially and required Michel to find people with multiple skills. “People who could only perform one kind of task, such as operating the dumper, did not fit in the team. Everybody needed to be able to work in different environments and perform different tasks.”

Each day also brought its own mini-surprises, including the unexpected breakdown of trucks, which needed to be fixed, sometimes inside the tent. “Such emergencies had to be handled very often and so we were used to it to some extent.”

While work in the tents was driven by the readiness of people to perform different kinds of work, all of these efforts had just one goal: to keep the logistics trail running as smoothly as possible.

To keep the supply chain running, the key challenge was to plan days ahead in order to fulfill customs requirements. For example, the customs office needed the security numbers of each container two days before they were transported. “Given the fact that we had limited space on the remediation site and that most of our containers were stacked one on top of the other, this was very challenging at times, and we needed to plan very carefully so that we were prepared for any eventuality.”

“That everything worked almost like clockwork in the end was not due only to planning. The real difference was made by the team members, all of whom were prepared to do the right thing whenever the situation demanded,” Michel said.