Table of contents

Table of contents Every move counts

Every move counts Up to the challenge

Up to the challengePublished on 01/06/2020

It was another hard day for the fledgling cell and gene team in Stein, but not because of the bad weather, which had taken an unexpected turn for the worse in mid-March in 2019. For eight hours, associates were training intensively, as they had been in the weeks and months before – hardwiring the myriad steps that their new job would soon require them to do faultlessly every day.

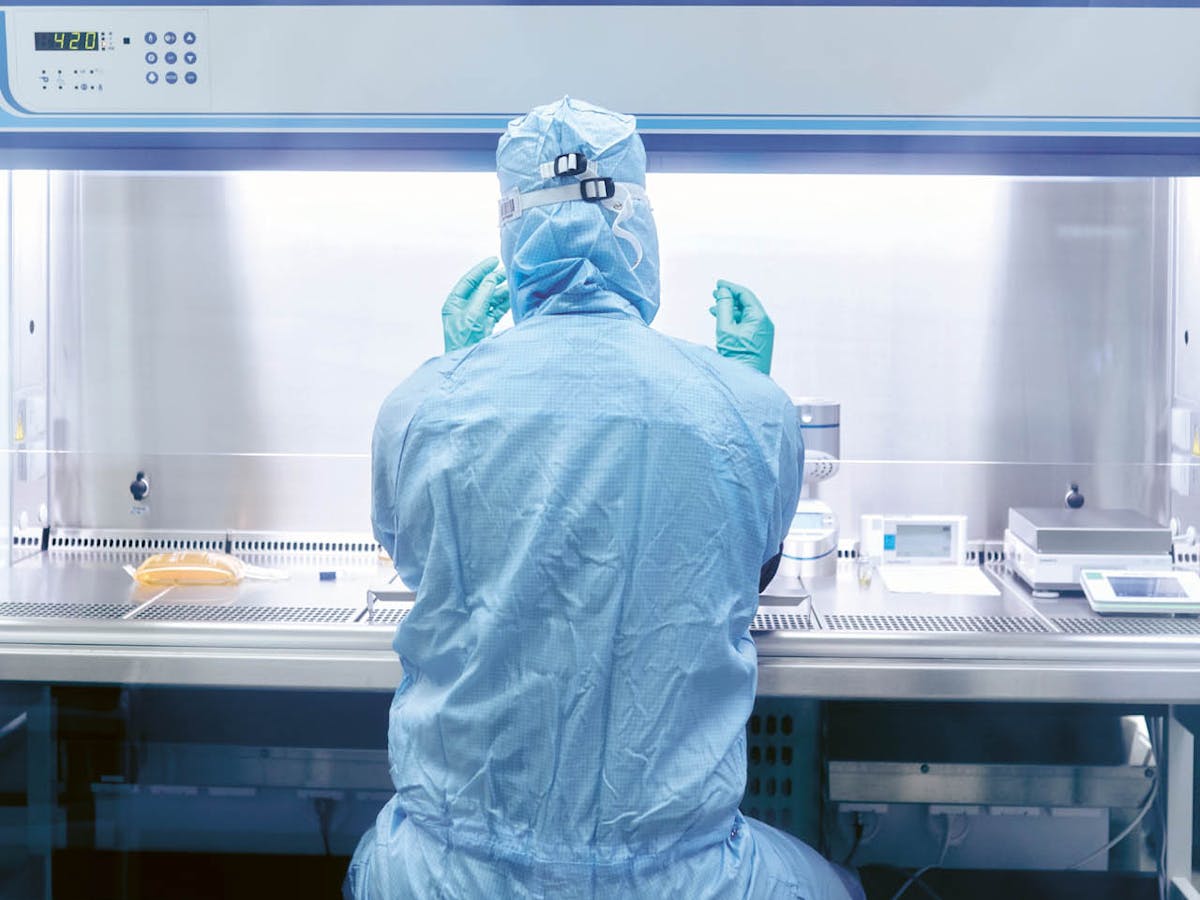

Exercising either in pairs, with one colleague verifying every move made by his or her peer, or under the supervision of a coach, all of the team members of the cell and gene unit were fully focused on the tasks at hand, each of them acutely aware of the high stakes.

A few months later, all of them knew, their dry run would come to an end and the first patient batch would arrive from a hospital at this new cell and gene facility, which is located roughly 30 kilometers from Basel. They would be responsible for genetically modifying patients’ T-cells and ready them to hunt for cancer. No room for mistakes. No room for second thoughts.

Bjoern Giner knew all about the tension which inevitably rises when the first batch is about to arrive. He has worked in Morris Plains for the past few years, where Novartis had built the first industrial cell and gene facility, and still vividly remembered being part of the team that executed a chimeric antigen receptor T-cell therapy, better known under its abbreviation CAR-T, for the first time.

“I had worked in drug discovery before, where you’re a long way from the patient. But with the move to the cell and gene unit in the United States, that changed completely,” Bjoern Giner explained, when I met him for a short chat with several of his colleagues after a day’s challenging work in Stein. “When we handled the first batch I felt nervous and excited at the same time. Never before in my career as a medical scientist did I feel so close to a single patient. Every step we took had a direct impact on a patient’s life. It was a completely different kind of work.”

Since his first batch, Bjoern has worked on hundreds of CAR-T therapies. Given his long experience in the field, he acted as a coach in Stein tasked to educate his new colleagues about the technical aspects of the complex production process, taking great pains to explain each incremental stage of the long procedure, which – in its entirety – fills a 1000-page manual.